Weuserecyclablematerialsthatlastovertimeandrespecttheenvironment.

Materials

Steel/Aluminum Coated

For each product and component made of steel, we select the most suitable raw materials and treatments based on our production cycle and the specific design requirements.

Our steel treatments include hot-dip and cold galvanizing, Sendzimir galvanization, cataphoresis, and primer coating.

For our aluminium products and components, we use sheet, extruded, or cast aluminium.

Subsequently, we apply polyester powder coating to steel, stainless steel, and aluminium, in compliance with the EN ISO 12944-2 standard.

We offer a wide range of standard RAL colours with a wrinkle finish, featuring various embossing levels. In cases where customization through stickers, pad printing, or screen printing is required, the finish is technically limited to matte or glossy smooth, depending on feasibility.

We also offer exclusive SABLE’ finishes, known for their unique metallic wrinkle texture.

Upon request, we provide several treatments and customizations, including coating in non-standard colours, smooth matte or glossy finishes, and anti-graffiti coatings.

The coating cycle can be Quality Steel certified upon request.

Stainless Steel

For our stainless steel products and components, we generally use AISI 304 or 304L steel. In cases where the installation environment is particularly aggressive, we recommend requesting AISI 316.

Our stainless steel typically features a satin or shot-peened finish, depending on the technical characteristics of the item.

Electropolishing treatment is also available upon request.

Corten Steel

Corten steel is a “living” material, constantly evolving over time. Its appearance is non-uniform, and each product features unique shades and coloration.

We sand our Corten products before carrying out our oxidation process, which has been specifically developed to minimize water consumption.

To reduce the natural release of oxide residues, protective treatments with anti-drip oil are available upon request.

In particularly saline environments, Corten may behave unpredictably, so we recommend carefully assessing its suitability for placement in such conditions.

Wood

For our products made of hardwood and thermally treated pine, we apply a pigmented water-based impregnation treatment. Upon customer request, the wood can be left in its natural state.

Products made from Okumé wood are always supplied with a water-based coating. The FSC certification is available upon request.

WPC (Wood Plastic Composite)

We have selected two different types of WPC (wood-plastic composite) for our products: ULTRA and PLUS. These two types are not to be considered interchangeable, as the choice depends on the technical requirements of each specific design.

HPL (High Pressure Laminate)

The HPL (high-pressure laminate) we have selected for our products is a material particularly well-suited for outdoor use. It is available in three color options: white, black, and taupe.

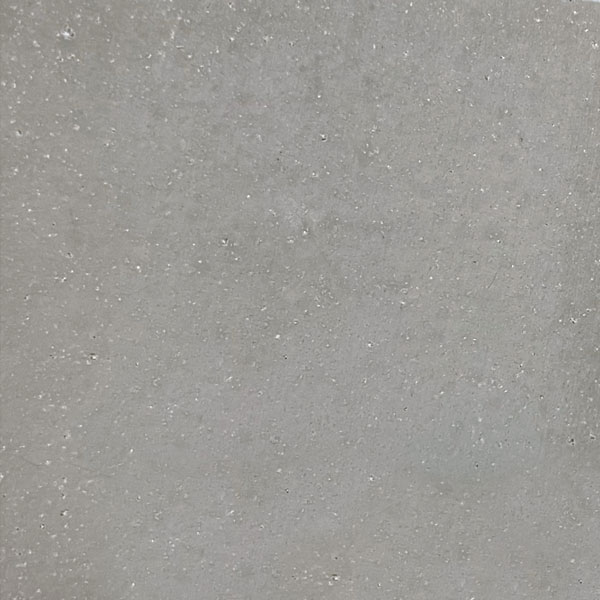

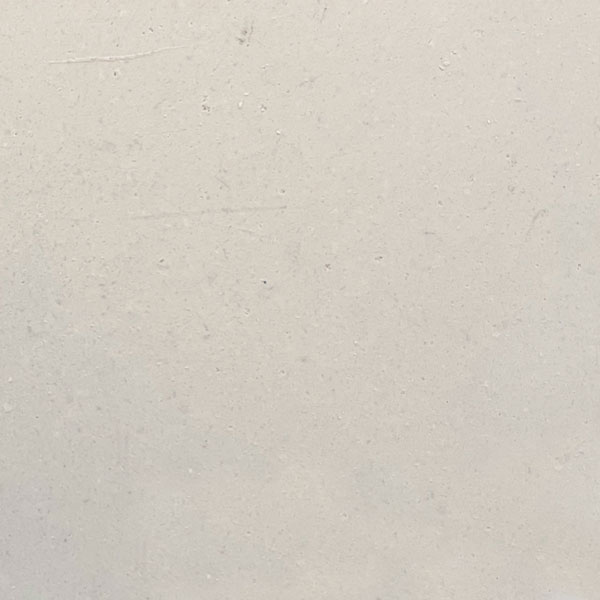

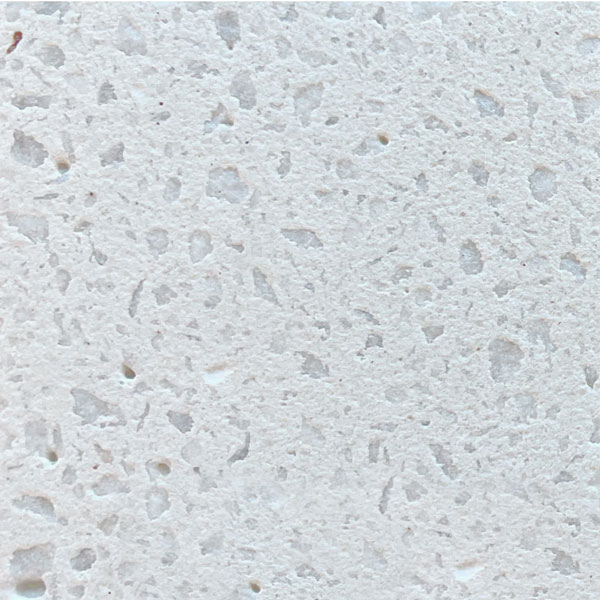

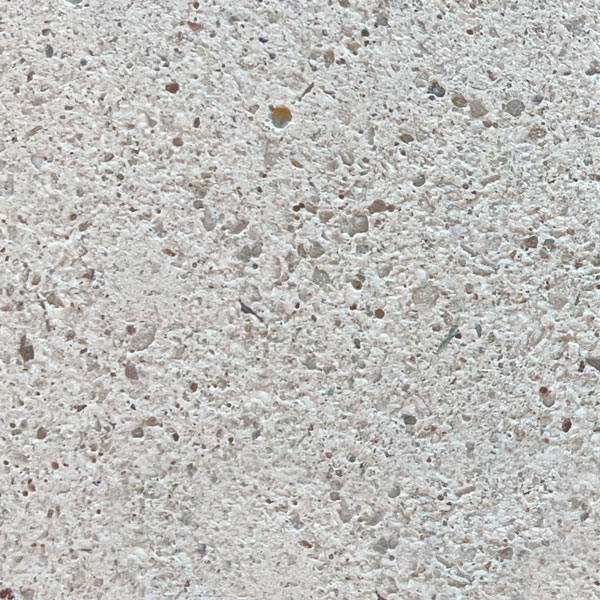

UHPC (Ultra High Performance Concrete)

Our UHPC (Ultra High Performance Concrete) is available in three color options: white, grey, and dark grey, and is supplied with an ALFA finish—a natural smooth surface.

Characterized by a textured appearance, UHPC may display cloudy, non-uniform color effects and fine surface cracking, which are natural characteristics of this type of material.

The finished products are treated with a protective coating, and an anti-graffiti treatment is available upon request.

HPC (High Performance Concrete)

Our HPC (High Performance Concrete) is available in three color options: white, grey, and dark grey, and is typically supplied with a VELLUTO finish—a natural smooth surface.

Characterized by a textured appearance, HPC may display cloudy, non-uniform color effects and fine surface cracking, which are natural features of this type of material.

Upon request, and where technically feasible, surface polishing can be carried out. The finished products are treated with a protective coating, and an anti-graffiti treatment is available upon request.

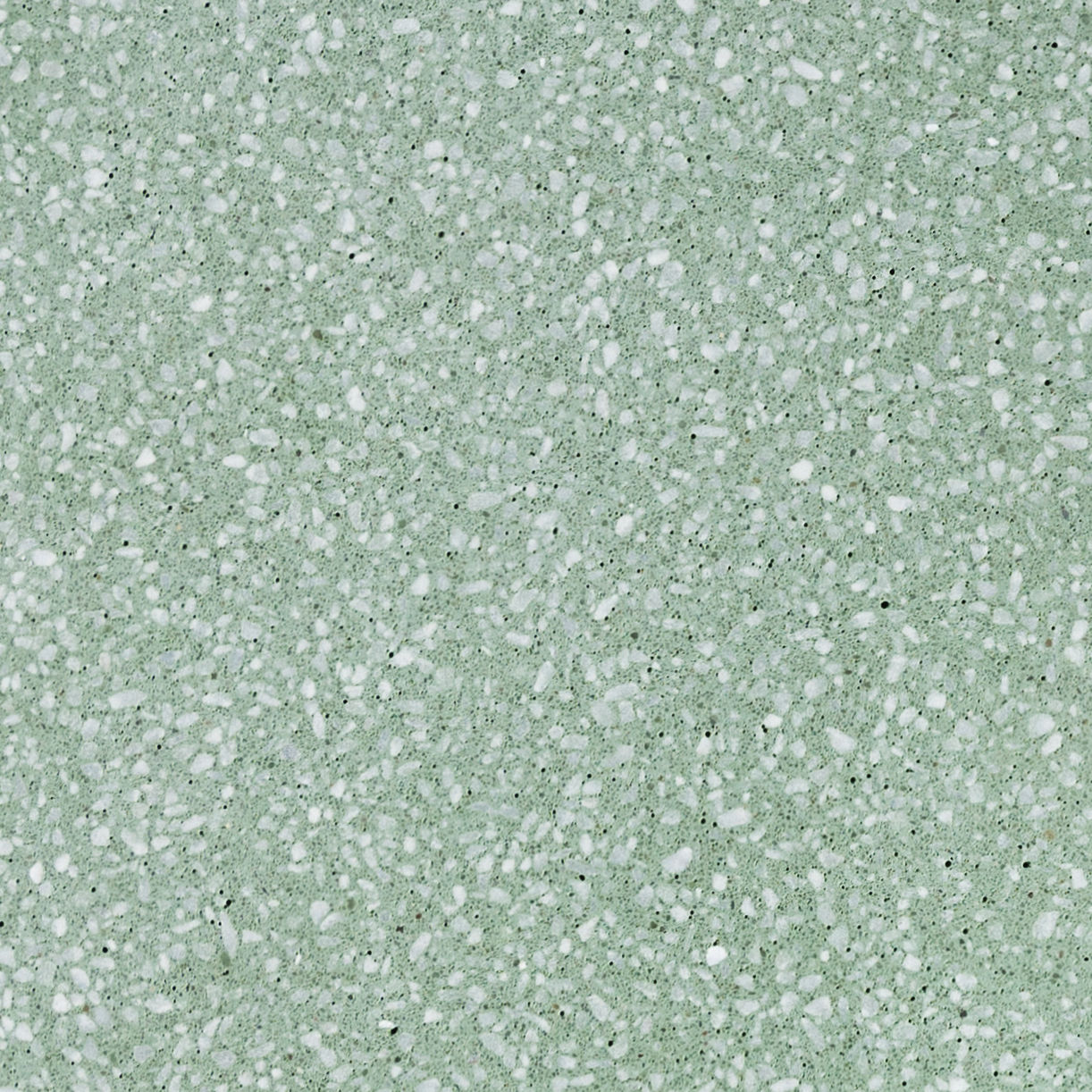

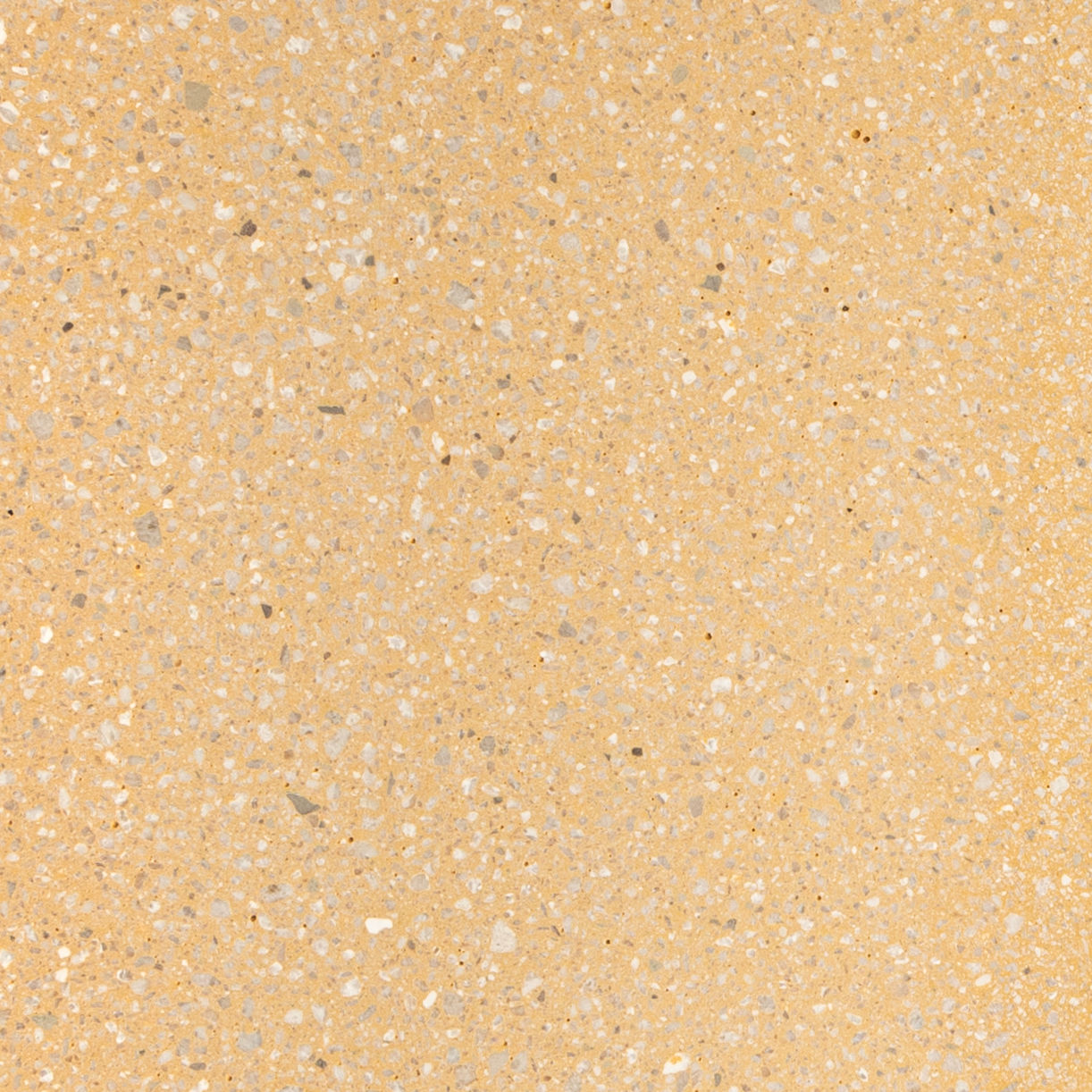

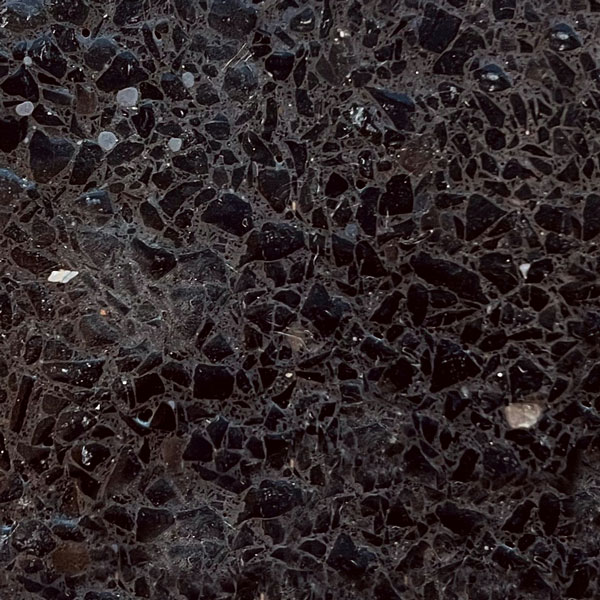

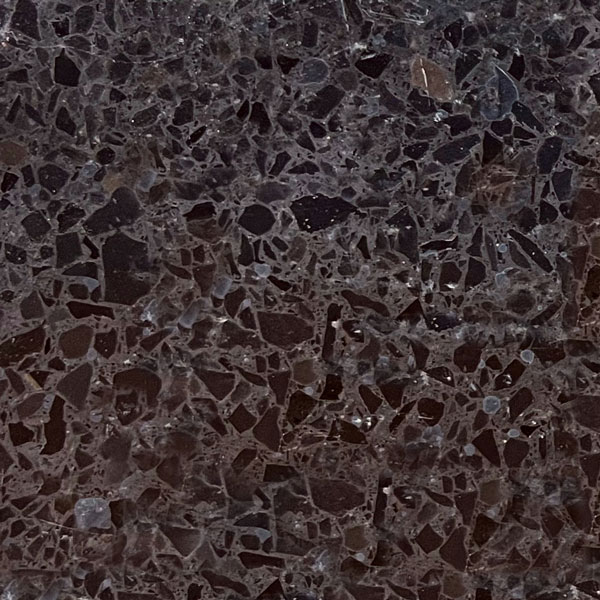

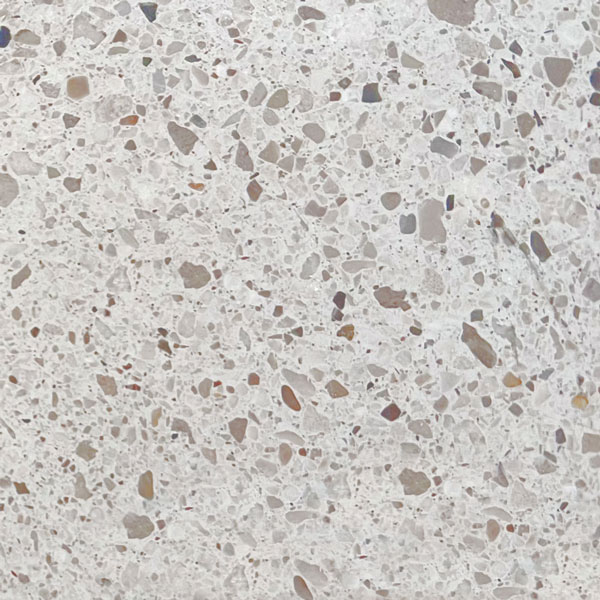

PDM (Reconstituted Stones)

Our PDM (Reconstituted Stone) is a blend of cement and aggregates that combines the strength of cement with the elegance of natural stone.

It is available in four options: white granite, grey granite, white marble, and black marble.

Our products are typically supplied with a sandblasted finish and brushed flat seating surfaces. Upon request, if the product allows, polishing can be performed.

The finished products are treated with a revitalizing coating, and an anti-graffiti treatment is available upon request.

Sintered stone

Sintered stone is an ultra-compact, carbon-neutral material produced through an industrial manufacturing process.

It is made from a blend of selected atomized natural minerals—such as feldspars, mineral oxides, clay, silicon, and many others—without any chemical additives, resins, or adhesives.

These minerals are compacted using industrial techniques that enhance the physical and mechanical properties of natural stone, resulting in a product that offers top-level performance.

Fiberglass

For some products, as an alternative to HPC (High Performance Concrete), Metalco offers fiberglass.

Fiberglass, or GRP (Glass Reinforced Plastic), is a type of plastic reinforced with glass fibers, typically in the form of non-woven fabric (TNT) or felt with randomly oriented fibers, impregnated with thermosetting resins. These harden after processing through the action of a catalyst and an accelerator.

An epoxy primer is then applied, followed by a polyurethane topcoat in a color of choice from Metalco’s RAL range.